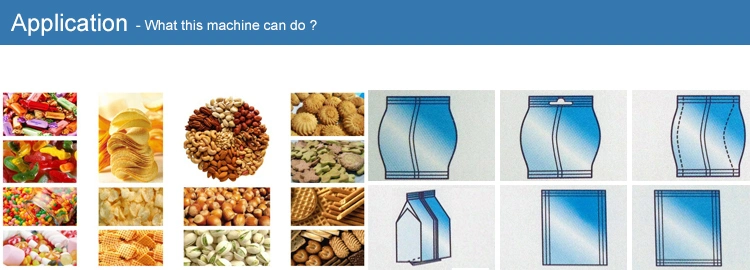

This machine is applicable for packing granule or irregular solidity in form of pillow pouch or gusset pouch, with different patterns of sealing, and different styles of cutting, which include processes of weighing, film-pulling, filling, pouch-making, sealing and cutting off, the detail application description as following table:

| Issue | Application Description |

| Applicable Pouches | One of the following scenarios can be selected for one machine: 1) Pillow / Flat Pouch 2) Gusset Pouch |

| Applicable Products | Granule or other irregular solidity such as candy, popped food, roasted seeds or nuts, etc |

| Applicable Packaging Material | Laminate Heat sealable packing materials such as OPP/PE,BOPP/OPP/PE,PET/AL etc |

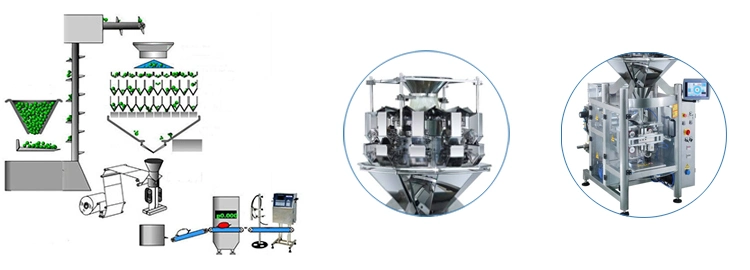

The working processes include: The machine pull laminate packaging film to the pouch forming devices, and go through the vertical sealing plate, in the meanwhile, the dosing device dose the product into the pouch, then will do the horizontal sealing and cutting off. Above is the typical working process diagram

Standard Features

• Products dosing, Filling, Laminate heat sealable pouch making and sealing.

• Stainless steel 304 structure and surface

• Weighing and Packaging PLC & HMI Control Integrated, More stable operation, Easy for parameter setting

• Simple changing of pouch former, to adapt different pouch size requirement

• Intelligent temperature controlling configuration, ensure the artistic and neat sealing

• Configure with packaging film pre-pulling device, to enable stable pouch making

• No film no filling, and easy to change the packaging film

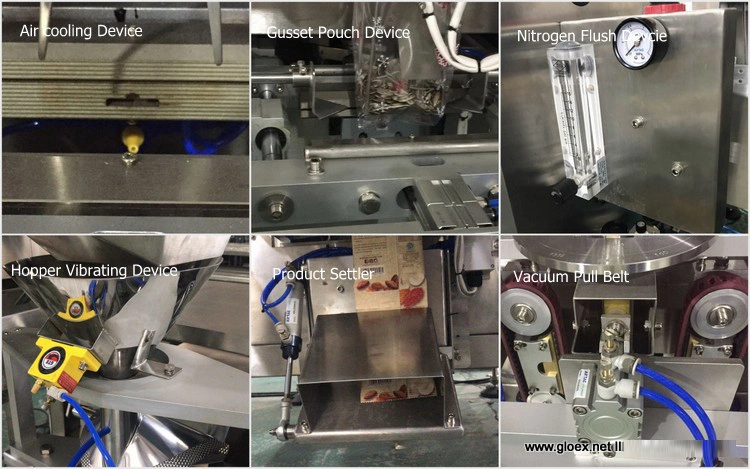

Optional Features

| Optional Features | Options/Description |

| Products Touching Parts | 1) Stainless Steel 304 2) Stainless Steel 316 |

| Sealing Patterns | 1) Checkerboard Pattern 2) Flat Line Pattern 3) Other customized pattern |

| Sachet Cut-off Shape | 1) Flat Cut-off 2) Serration Cut-off 3) Linking Pouch Cut-off |

| Tear Notch | To make tear notch with specific shape |

| Code Printing | 1) Pressing Type Coder built-in 2) Ribbon Code Printing 3) Code Inkjet Printing |

| Hang Hole | To make hang hole with specific shape |

| Dust Collecting Device | To collect the dust during dosing |

| Inflating & Deflating | 1) Air / Nitrogen Inflating 2) Air Deflating |

| Packaging Film Correction Device | To ensure correct movement of the packaging film pulling |

| Pouch Types | 1) Flat/Pillow Pouch 2) Gusset Pouch |

Practically, to form such a production line, most of the manufacturers separate the weigher and the vertical packaging machine. But this type machine, integrate the weigher and packaging unit in one machine, and has its advantages as indicated in the following table:

| Gloex Selected | Other Practice | Advantage |

Production line includes

| Production Line includes

|

|

| Catalogue/1T-xxxxx | 1040-08 | 1440-05 | 1040-10 | 1250-10 | 1450-08 |

| HMI Dimension(inch) | 10.4 | 10.4 | 10.4 | 10.4 | 10.4 |

| Heads of Weigher | 10 | 14 | 10 | 12 | 14 |

| Bucket Volume(L) | 0.8 | 0.5 | 1.0 | 1.0 | 0.8 |

| Single Weighing Range(g) | 10-500 | 10-500 | 10-1000 | 10-1000 | 10-1000 |

| Max Weighing Range(g) | 1000 | 1000 | 1000 | 1000 | 1000 |

| Weighing Accuracy(g) | +/-0.3-1.5 | +/-0.3-1.5 | +/-0.5-1.5 | +/-0.5-1.5 | +/-0.5-1.5 |

| Max Film Width(mm) | 400 | 400 | 400 | 500 | 500 |

| Pouch Size-Length(mm) | 50-230 | 50-230 | 50-230 | 50-290 | 50-290 |

| Pouch Size-Width(mm) | 60-190 | 60-190 | 60-190 | 60-240 | 60-240 |

| Max Packing Speed (Pouches/min) | 60 | 90 | 60 | 90 | 90 |

| Power Consumption(kW) | 4.0 | 4.0 | 4.0 | 5.0 | 4.0 |

| Power Requirement(V/Hz) | 220V 50/60HZ | ||||

| Vertical Sealing Method | Servo Motor | Servo Motor | Servo Motor | Servo Motor | Servo Motor |

| Horizontal Sealing Method | Pneumatic | Servo Motor | Pneumatic | Servo Motor | Servo Motor |

| Compress Air Requirement | 0.6 Mpa | 0.6 Mpa | 0.6 Mpa | 0.6 Mpa | 0.6 Mpa |

| Compress Air Consumption | 0.3m3/min | 0.2m3/min | 0.3m3/min | 0.3m3/min | 0.3m3/min |

| Approximate Net Weight(kg) | 500 | 540 | 550 | 650 | 650 |

| Dimension(mm) | 1556*1366*2078 | 1556*1366*2078 | 1530*1300*2300 | 1630*1320*2600 | 1630*1320*2600 |

Except for the engineering of the machine, the key components configuration will determine the quality of the machine or system, below is the shortlist configuration of the key components:

| No | Components | Material / Short List |

| 1 | Products Touching Parts | Stainless Steel 304 as the standard, Stainless Steel 316, 316L at the Buyer's option |

| 2 | Structure / Support | Carbon Steel or High Class Aluminum |

| 3 | Main Surface | Stainless Steel 304 |

| 4 | Programmable Logic Controller | Delta, Siemens, Mitsubishi, Panosonic |

| 5 | Touch Screen | Weinview, Siemens, Delta, Kinco, Panosonic |

| 6 | Stepper/Servo Motor | Teco, Delta, Panosonic, Leadshine |

| 7 | Frequency Convertor | Delta, Schneider, Leadshine |

| 8 | Key Electric Components | Schneider, Chint, Ls, Ark |

| 9 | Key Protection & Relay | Schneider |

| 10 | Cylinder, Filter | Airtac, SMC |

| 11 | Photocell Sensor | Autonics, Keyence, Leuze, Panosonic, Datalogic |

| 12 | Vacuum Sucker | Airtac, Sunx |

| 13 | Temperature Controller | Omron |